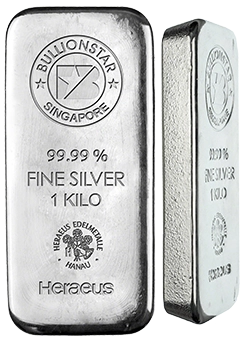

BullionStar Blogs

BullionStar is renowned for presenting original research and expertise

covering the most important trends in the precious metals markets.

Customer Support Languages

Your Account

BullionStar is renowned for presenting original research and expertise

covering the most important trends in the precious metals markets.

Buy from BullionStar

Sell to BullionStar

Gold

Silver

Platinum

| We use cookies to enhance the user experience, analyse traffic and handle essential functionality. By using our website, you accept that cookies are used. Learn more in our Privacy Policy. |

OK

|